Mercedes corrosion protection is an advanced technology addressing galvanic reactions between contrasting metals in vehicles, leading to accelerated corrosion and structural damage. It creates a multi-layered barrier isolating different metals, preventing electron flow and chemical reactions that cause rust. This innovative solution benefits both modern and classic vehicles, maintaining integrity of mixed metal surfaces and preserving aesthetics while reducing repair costs, especially for collision repairs and storage protection.

“Mercedes Corrosion Protection offers a revolutionary approach to safeguarding mixed metal surfaces, preventing galvanic reactions that often lead to premature deterioration. This article delves into the intricate world of corroding metals, exploring the science behind Mercedes’ innovative solution. We’ll uncover how their corrosion inhibitors work, highlight the myriad benefits, and discuss their diverse applications, making Mercedes corrosion protection a game-changer in industries demanding robust, long-lasting solutions.”

- Understanding Galvanic Reactions in Mixed Metals

- Mercedes Corrosion Protection: The Science Behind It

- Benefits and Applications of Mercedes Corrosion Inhibitors

Understanding Galvanic Reactions in Mixed Metals

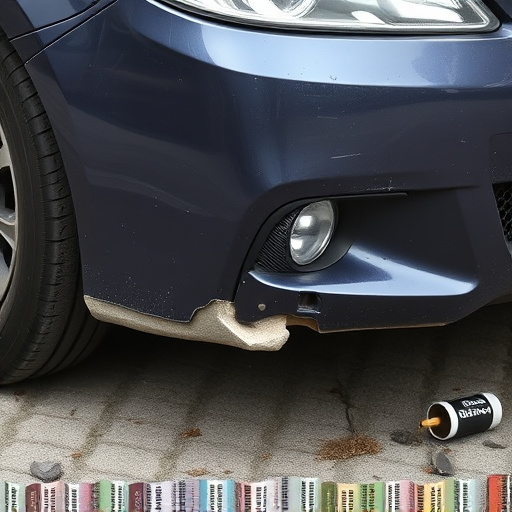

Galvanic reactions occur when different metals are in contact with each other and exposed to an electrolyte, such as moisture or salt. In the context of vehicles, this often happens when various metallic components, like steel and aluminium, are joined together on a car’s body. Without proper protection, these contrasting metals can experience accelerated corrosion due to the galvanic reaction, leading to weakened joints and structural damage over time. This is especially relevant for modern cars that extensively use lightweight yet corrosive aluminium alloys in their construction.

Mercedes corrosion protection plays a crucial role in mitigating these issues. By applying specialised coatings and treatments, Mercedes ensures that mixed metal surfaces are protected against galvanic reactions during manufacturing and throughout the vehicle’s life. This not only enhances the structural integrity of the car body but also extends the lifespan of components, delaying or even preventing the need for costly auto body repairs, including scratch repair and more extensive car body restoration work.

Mercedes Corrosion Protection: The Science Behind It

Mercedes Corrosion Protection is a cutting-edge technology designed to safeguard vehicles, particularly those at risk due to their age or complex metal structures. This innovative protection system works by employing advanced scientific principles to prevent galvanic corrosion in mixed metals. When different types of metal come into contact and are exposed to moisture, they can undergo a chemical reaction leading to rust and degradation. Mercedes’ solution involves a multi-layered barrier that isolates these metals, inhibiting the flow of electrons and preventing the damaging galvanic reaction.

The science behind this protection is rooted in understanding how corrosion forms and then using strategic materials to disrupt that process. By creating an insulative layer on the vehicle’s body, especially at joints and creases where corrosion often starts, the Mercedes system ensures longevity. This protective coating is crucial for both modern vehicles leaving the dealership and classic car restorers looking to preserve historical precision. Whether in a vehicle body shop or a collision repair shop, Mercedes corrosion protection offers a game-changer solution for maintaining the integrity of mixed metal surfaces.

Benefits and Applications of Mercedes Corrosion Inhibitors

Mercedes corrosion protection offers a multitude of benefits for both personal and commercial vehicle owners. By inhibiting galvanic reactions in mixed metals, these inhibitors prevent the rapid deterioration that often occurs when different metal components come into contact with each other, especially in the presence of moisture. This is particularly beneficial for those operating collision repair shops or automotive body shops, as it significantly reduces the need for frequent bumper repairs and other metal replacements.

The applications of Mercedes corrosion inhibitors are vast, from protecting intricate car parts during long-term storage to enhancing the longevity of newly repaired panels like those in a bumper. Their ability to create an insulating barrier between metals ensures that even minor scratches or nicks, which could otherwise lead to corrosion, remain largely unaffected. This not only saves owners time and money but also contributes to maintaining the overall aesthetics and resale value of vehicles, making them a valuable addition to any automotive care routine in both collision repair shops and personal garages alike.

Mercedes corrosion protection, with its innovative approach to inhibiting galvanic reactions in mixed metals, offers a revolutionary solution for maintaining vehicle durability. By understanding the science behind this technology and its benefits in preventing corrosive damage, it’s clear that Mercedes corrosion inhibitors are an indispensable tool in safeguarding automotive components. This advanced method ensures longer-lasting vehicles and reduced maintenance costs, making it a game-changer in the industry.