Mercedes Corrosion Protection: Shielding Your Vehicle from Salt and Road Harm

Mercedes provides a robust corrosion protection system tailored for regions with harsh climates and…….

In the realm of automotive engineering, ensuring the longevity and integrity of vehicles is a paramount concern. Among various critical aspects, corrosion protection stands out as a cornerstone for premium vehicle manufacturers like Mercedes-Benz. This article delves into the intricate world of Mercedes corrosion protection, exploring its historical development, global impact, technological innovations, regulatory landscape, and future prospects. By examining these facets, we aim to provide an in-depth understanding of how this protective measure contributes to the overall quality and durability of Mercedes vehicles, setting a benchmark for the industry.

Mercedes corrosion protection refers to a comprehensive system and set of processes designed to safeguard automobile components from the detrimental effects of corrosion. It involves a multi-layered approach that encompasses various materials, coatings, treatments, and maintenance strategies. The primary goal is to preserve the structural integrity and aesthetic appeal of vehicles over their lifespan, ensuring they remain in top condition even under harsh environmental conditions.

The core components of Mercedes corrosion protection include:

Coatings and Sealants: Advanced protective coatings and sealers are applied to metal surfaces during manufacturing or as after-treatment. These coatings create a barrier against moisture, salt, and other corrosive elements, significantly slowing down the corrosion process. Examples range from epoxy coatings for underbody components to high-quality paints with anti-corrosion additives.

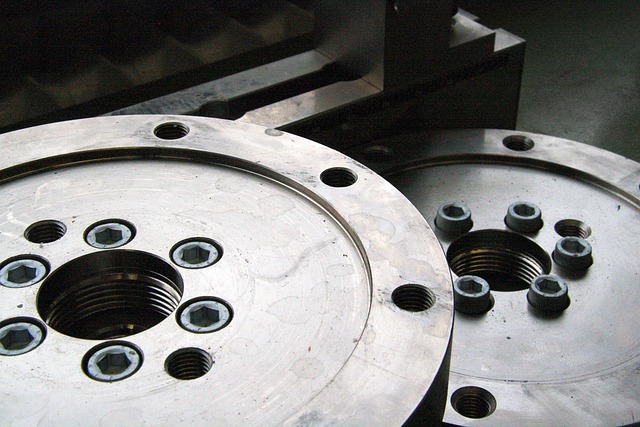

Alloy Selection: Mercedes engineers carefully select lightweight yet highly resistant alloy blends for various vehicle parts. Alloys like aluminum and specific stainless steel varieties offer excellent corrosion resistance, ensuring that structural elements remain intact even in corrosive environments.

Galvanization: This process involves coating metal surfaces with a layer of zinc, which acts as an sacrificial anode, protecting underlying metals from corrosion. Many Mercedes components, especially those exposed to high moisture levels, benefit from galvanized steel for extended protection.

Anti-Corrosion Treatments: Specialized treatments are applied post-production to enhance corrosion resistance. These may include phosphating, which provides a protective layer on metal surfaces, and immersion in anti-corrosion baths for certain parts.

Maintenance Practices: Regular maintenance plays a vital role in Mercedes’ corrosion protection strategy. Scheduled washings, underbody inspections, and prompt repair of any corrosion-related damage contribute to the long-term effectiveness of these protections.

The historical evolution of Mercedes corrosion protection can be traced back to the early 20th century when the automotive industry began addressing the challenges posed by corrosive elements. Over time, Mercedes has consistently pushed the boundaries, incorporating innovative materials and techniques to enhance its corrosion protection measures.

Mercedes’ corrosion protection strategies have had a profound global impact, setting industry standards for quality and durability. The company’s commitment to this aspect is particularly notable in regions with diverse climatic conditions, where vehicles are exposed to varying levels of humidity, salt content in roads, and temperature extremes.

Europe: With its diverse weather patterns, Europe presents unique challenges for corrosion protection. Mercedes has tailored its strategies to accommodate the region’s high moisture levels and salty road surfaces, ensuring that vehicles remain robust in countries like Germany, France, and the UK.

North America: The American market, characterized by varying climates and salt-treated roads during winter, demands stringent corrosion protection measures. Mercedes’ North American models are engineered to withstand these conditions, showcasing the brand’s adaptability.

Asia Pacific: In regions like Japan and South Korea, where high humidity levels can accelerate corrosion, Mercedes has implemented advanced protective coatings and treatments, ensuring its vehicles remain in top condition for local consumers.

Lightweighting: A growing trend in the automotive industry is lightweighting, which reduces vehicle weight to improve fuel efficiency. However, it also presents a challenge as lighter materials may require enhanced corrosion protection strategies. Mercedes has addressed this by developing specialized alloys and protective coatings tailored for lightweight components.

Electric Vehicles (EVs): The rise of electric vehicles introduces new considerations for corrosion protection, primarily focusing on protecting the battery packs from moisture and corrosive elements. Mercedes, with its growing EV portfolio, is at the forefront of developing effective corrosion prevention measures for these innovative vehicles.

Sustainability: There is a global push towards sustainable practices, including in the automotive sector. Mercedes is responding by exploring eco-friendly materials and processes that minimize environmental impact while maintaining robust corrosion protection.

The economic implications of Mercedes corrosion protection are far-reaching, impacting both the manufacturer and consumers.

Premium Pricing: Mercedes vehicles, known for their superior quality and durability, command premium prices in the market. Effective corrosion protection is a significant factor contributing to this pricing strategy, as it ensures that owners enjoy the full spectrum of vehicle performance and aesthetics over an extended period.

Reputation and Brand Value: A strong reputation for corrosion resistance enhances Mercedes’ brand value, attracting customers who prioritize long-term investment in their vehicles. This can lead to increased customer loyalty and repeat purchases.

Research and Development (R&D): Mercedes invests heavily in R&D to stay at the forefront of corrosion protection technology. These investments drive innovation, ensuring the company continues to meet evolving industry standards and customer expectations.

Supply Chain Management: The implementation of robust corrosion protection measures requires a reliable supply chain for high-quality materials and components. Mercedes’ strategic partnerships with suppliers play a crucial role in maintaining consistent protection levels across its vehicle range.

For consumers, the economic implications are primarily related to cost savings over the vehicle’s lifespan. Effective corrosion protection reduces the need for frequent repairs and replacement parts, which can be significant cost savers, especially for high-end Mercedes models. Moreover, the resale value of vehicles with a proven track record of corrosion resistance tends to remain higher, providing owners with better returns when selling their cars.

Mercedes has been at the forefront of technological advancements in corrosion protection, continuously refining its methods to stay ahead of industry trends and evolving environmental conditions.

Smart Coatings: Mercedes has developed intelligent coatings that can self-repair minor damages and adapt to changing environmental conditions. These coatings contain micro-encapsulated chemicals that resurface when scratched or corroded, restoring protective properties.

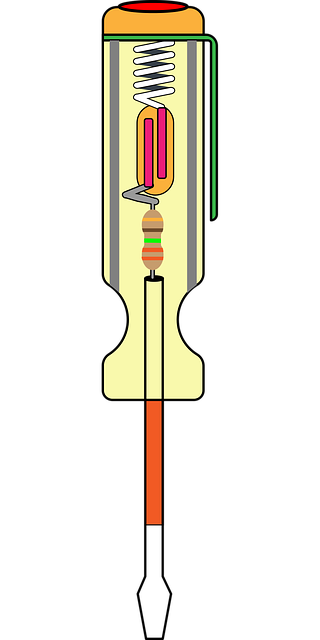

Corrosion-Sensing Systems: Some advanced Mercedes models incorporate sensors that monitor corrosion-prone areas, providing early warnings to owners through in-cabin displays or connected apps. This proactive approach allows for timely intervention and maintenance.

Laser Technology: Precision laser treatments are used to enhance the adhesion of protective coatings, ensuring long-lasting protection. This technology is particularly useful for intricate components where traditional application methods may be less effective.

Digital Manufacturing: Digital technologies enable precise control over material selection, coating application, and assembly processes, resulting in superior corrosion protection. Mercedes leverages advanced robotics and AI to achieve consistent quality across its production lines.

The development and implementation of corrosion protection measures are influenced by various policies and regulations, which vary across regions. These frameworks ensure that vehicle manufacturers adhere to certain standards, ultimately benefiting consumers.

Environmental Protection Agency (EPA) in the United States: The EPA sets emission and fuel efficiency standards, indirectly influencing corrosion protection requirements, especially for EVs. The agency also regulates the use of certain chemicals, which may impact protective coatings.

European Union (EU) Regulations: The EU’s automotive sector regulations cover various aspects, including material safety, waste management, and end-of-life vehicle recycling. These guidelines shape Mercedes’ approach to corrosion protection in European markets.

Global Auto Industry Alliance (GAIA): This industry group promotes sustainable practices, including corrosion protection, through voluntary agreements. GAIA’s initiatives often provide a framework for manufacturers like Mercedes to demonstrate their commitment to environmental stewardship.

Product Liability Laws: These laws hold manufacturers responsible for the safety and durability of their products, including protection against corrosion. Mercedes must ensure that its vehicles meet these legal standards to avoid potential liabilities.

Warranty Regulations: In many jurisdictions, warranty policies include coverage for corrosion damage. Mercedes’ warranties reflect these regulations, offering peace of mind to consumers regarding corrosion-related issues.

Despite its numerous advantages, Mercedes corrosion protection has not been without challenges and criticisms. Addressing these issues is crucial to maintaining the brand’s reputation for quality and innovation.

Cost of Implementation: Developing and implementing advanced corrosion protection technologies can be expensive, especially for smaller manufacturers. Mercedes, as a premium brand, can absorb these costs more readily but must consider the affordability of its vehicles for mass markets.

Regional Variability: Adapting to diverse climatic conditions across regions remains a challenge. While Mercedes has made significant strides, local weather patterns may still require tailored solutions, potentially increasing complexity and cost.

Material Compatibility: Ensuring compatibility between various materials, coatings, and treatments can be difficult. Inconsistencies in material selection or application processes may compromise the overall corrosion protection strategy.

Over-reliance on Coatings: Some critics argue that Mercedes overemphasizes protective coatings, potentially neglecting other essential aspects of corrosion prevention. To address this, the company must strike a balance by incorporating multiple protection layers, including alloy selection and anti-corrosion treatments.

Environmental Concerns: While Mercedes promotes eco-friendly practices, certain protective materials and coatings may have environmental impacts. The company should continue to explore sustainable alternatives and disclose these materials’ environmental profiles transparently.

Long-term Performance Data: Critics often demand long-term performance data for corrosion protection claims. Mercedes can meet this demand by conducting extensive field tests and sharing results, reinforcing consumer confidence in its products.

To gain practical insights into Mercedes corrosion protection, let’s explore a few case studies from different regions, highlighting successful implementations and the lessons learned.

The iconic Mercedes G-Class, known for its off-road capabilities, faces harsh environmental conditions in Africa, including extreme temperatures, high humidity, and dusty terrains. To tackle these challenges, Mercedes implemented a robust corrosion protection system that includes:

Specially Formulated Coatings: A unique coating with excellent resistance to heat, dust, and moisture was developed for the G-Class. This coating is applied in multiple layers during manufacturing.

Galvanized Steel Bodywork: The vehicle’s body is primarily constructed from galvanized steel, providing a durable barrier against corrosion.

Regular Maintenance Programs: Local Mercedes dealerships offer specialized maintenance packages tailored to African conditions, ensuring regular underbody inspections and prompt repairs.

Lessons Learned: This case illustrates how Mercedes tailors its corrosion protection strategies to specific regional challenges, resulting in a highly durable vehicle suited for demanding environments.

The all-electric Mercedes EQS, designed for the harsh winters of Northern Europe, required innovative corrosion protection measures for its battery packs and other sensitive components. The solutions implemented include:

Waterproof Housing: The battery pack is housed in a waterproof compartment, preventing moisture ingress, a common concern with electric vehicles.

Corrosion-Inhibiting Fluids: Special fluids are used to inhibit corrosion within the vehicle’s electrical systems, addressing the challenges posed by salt and humidity.

Regular Software Updates: Mercedes provides over-the-air software updates to optimize battery performance and implement enhanced corrosion prevention algorithms.

Lessons Learned: This case showcases how Mercedes adapts its corrosion protection strategies for EVs, focusing on protecting critical components while leveraging digital technologies for proactive monitoring.

As the automotive industry continues to evolve, Mercedes corrosion protection must adapt and innovate to stay ahead of emerging trends and meet future challenges. Here are some potential growth areas and strategic considerations:

Advanced Materials: The development of new alloys, composite materials, and protective coatings will be crucial in enhancing corrosion resistance while reducing weight and improving sustainability.

Digitalization and Connectivity: Mercedes can leverage digital technologies to create intelligent corrosion monitoring systems, predictive analytics, and remote diagnostic tools, enabling proactive maintenance.

Sustainable Practices: The company should continue to explore eco-friendly materials and processes, such as biodegradable coatings and recycled content, to meet growing consumer demand for sustainable products.

Global Harmonization: Mercedes can contribute to global standards for corrosion protection, ensuring consistent quality across markets while reducing the cost of compliance for both manufacturers and consumers.

Collaboration and Partnerships: Strategic alliances with research institutions and industry peers can accelerate innovation in corrosion protection technologies, fostering a collaborative ecosystem.

Mercedes corrosion protection is a testament to the company’s unwavering commitment to quality, durability, and customer satisfaction. Through a comprehensive understanding of corrosion mechanisms, innovative materials, and advanced technologies, Mercedes has established itself as a leader in this critical aspect of automotive engineering.

As the industry continues to evolve, Mercedes’ ongoing investments in research, sustainable practices, and digital transformation will ensure that its corrosion protection strategies remain cutting-edge. This dedication not only safeguards the integrity of its vehicles but also enhances consumer trust and loyalty, solidifying Mercedes’ position as a premium brand synonymous with excellence.

Q: How does Mercedes ensure the long-term effectiveness of its corrosion protection?

A: Mercedes employs a multi-layered approach, combining advanced coatings, alloy selection, anti-corrosion treatments, and regular maintenance practices to ensure long-term protection. They also conduct extensive field tests and provide performance data for consumer transparency.

Q: Are there any environmental concerns associated with Mercedes corrosion protection materials?

A: While Mercedes promotes sustainability, some protective materials may have environmental impacts. The company is committed to exploring eco-friendly alternatives and disclosing material profiles transparently to address these concerns.

Q: How do regional differences affect the corrosion protection strategies for Mercedes vehicles?

A: Mercedes tailors its protection measures to accommodate diverse climatic conditions. For example, models destined for regions with high humidity or salt content in roads receive specialized treatments and coatings to ensure robust performance.

Q: Can I contribute to better corrosion protection as a consumer?

A: Yes! Regular maintenance, including washing and underbody inspections, plays a vital role in extending the lifespan of corrosion protection. Promptly addressing any signs of corrosion damage is also beneficial. Informed consumers can make choices that support sustainable practices, influencing manufacturers’ long-term strategies.

Mercedes provides a robust corrosion protection system tailored for regions with harsh climates and…….

Mercedes corrosion protection is a multi-layer system designed to safeguard vehicle exteriors from e…….

Mercedes vehicles, though renowned for luxury and performance, are prone to corrosion from factors l…….

Mercedes corrosion protection is a specialized need for AMG models due to their demanding performanc…….

Mercedes corrosion protection is a crucial step after vehicle repairs, safeguarding metal integrity…….

Mercedes corrosion protection is a multi-layered, meticulously engineered system that shields vehicl…….

Mercedes corrosion protection is a multi-layered barrier system designed to safeguard vehicles from…….