Mercedes corrosion protection is vital for post-accident repair, preserving structural integrity and aesthetic value of premium Mercedes vehicles. It involves meticulous surface preparation, advanced technologies like electrostatic painting and specialized primers to create an impenetrable barrier against moisture, ensuring long-lasting protection that maintains brand value and original paint quality. Skilled technicians use strategic methods and high-quality parts to protect against future corrosion during restoration.

Mercedes vehicles are renowned for their luxury and durability, but even high-quality cars aren’t immune to corrosion. Understanding Mercedes corrosion protection is crucial in post-accident repair protocols. This article delves into the basics of Mercedes corrosion protection, its integral role in strategic repair strategies, and best practices for effective implementation. By exploring these aspects, you’ll gain valuable insights into ensuring top-tier repairs for Mercedes vehicles post-incident.

- Understanding Mercedes Corrosion Protection Basics

- Role in Post-Accident Repair Strategies

- Best Practices for Effective Implementation

Understanding Mercedes Corrosion Protection Basics

Mercedes corrosion protection is a critical component of post-accident repair protocols for several reasons. At its core, it involves using specialized techniques and materials to safeguard the vehicle’s structural integrity and appearance against future rusting and deterioration. This process begins with meticulous surface preparation, ensuring all damaged areas are thoroughly cleaned and treated to prevent water penetration, a primary cause of corrosion.

Auto body shops offering Mercedes corrosion protection services employ advanced technologies like electrostatic painting and innovative primers designed to create a robust barrier between the metal and potential moisture sources. These measures are crucial for maintaining the car’s value and aesthetics, especially given the brand’s premium positioning. Vehicle repair services that integrate corrosion protection not only enhance the longevity of Mercedes vehicles but also ensure customers receive top-tier car paint services that match the original manufacturer standards.

Role in Post-Accident Repair Strategies

Mercedes corrosion protection plays a pivotal role in effective post-accident repair strategies. In the immediate aftermath of a collision, whether it’s a minor fender bender or a more severe crash, the car’s exterior and underlying components are vulnerable to rust and corrosion. These detrimental effects not only compromise the structural integrity of the vehicle but also impact its overall aesthetic appeal and resale value.

Implementing robust corrosion protection measures during the collision repair process is essential for restoring the car to its pre-accident condition. Skilled technicians employ specialized techniques, such as applying protective coatings and utilizing high-quality replacement parts, to safeguard against future corrosion. This meticulous approach ensures that not only the visible repairs but also the hidden components of the car body restoration are secured, guaranteeing both the safety and longevity of the vehicle on the road.

Best Practices for Effective Implementation

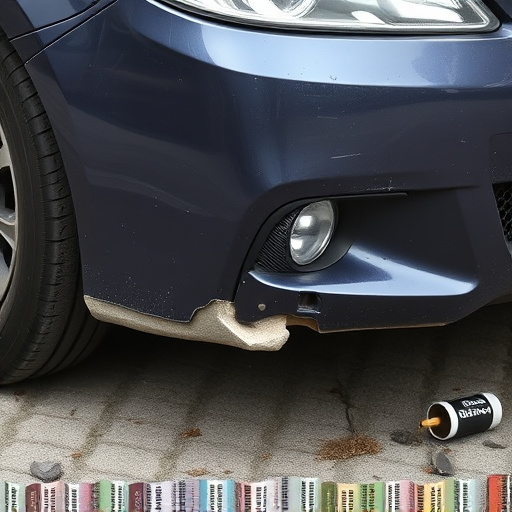

Implementing effective Mercedes corrosion protection is a multifaceted process that requires meticulous attention to detail. Before initiating any post-accident repair, it’s crucial to assess the extent of corrosion and plan an appropriate strategy. This includes meticulously cleaning the affected areas to remove any debris or contaminants that could hinder the protective coatings’ adherence.

The best practices involve utilizing specialized primers and undercoatings designed specifically for Mercedes vehicles, ensuring maximum compatibility and durability. Frame straightening techniques play a vital role in minimizing corrosion spread; by carefully straightening and aligning damaged components, collision repair shops can prevent further metal degradation. Ultimately, the successful integration of these best practices leads to superior automotive restoration outcomes, guaranteeing the longevity and aesthetics of Mercedes vehicles post-repair.

Mercedes corrosion protection is an integral part of modern post-accident repair protocols, ensuring vehicles not only look as good as new but also withstand future elements. By understanding the basics and implementing best practices, repair shops can deliver high-quality services that preserve the value and longevity of Mercedes-Benz models. This strategy not only benefits owners but also contributes to the overall sustainability of automotive repairs, making it a key consideration in today’s market.