Mercedes corrosion protection is a crucial step after vehicle repairs, safeguarding metal integrity and aesthetic appeal by preventing rust formation. Professionals apply specialized treatments and coatings using innovative technologies, creating a barrier against moisture, salt, and environmental factors that weaken metal surfaces. This process involves thorough cleaning, undercoat primer, even coats of high-quality Mercedes corrosion protection coating, and a clear coat, ensuring durability and restoring the car's glossy finish. To maximize its longevity, follow best practices like proper surface preparation, regular maintenance, prompt damage repair, and protection against harsh weather conditions.

Mercedes owners know the brand’s commitment to quality and durability. However, even with robust manufacturing, panel repairs or welds can introduce new entry points for corrosion. Understanding and applying proper Mercedes corrosion protection is essential to preserve your vehicle’s integrity and value. This guide explores why post-repair protection matters, provides a step-by-step application process, and offers best practices for maintaining long-lasting corrosion resistance for your Mercedes.

- Understanding Mercedes Corrosion Protection: The Why and What

- Applying Corrosion Protection After Panel or Weld Repairs: Step-by-Step Guide

- Best Practices and Maintenance Tips for Longevity of Mercedes Corrosion Protection

Understanding Mercedes Corrosion Protection: The Why and What

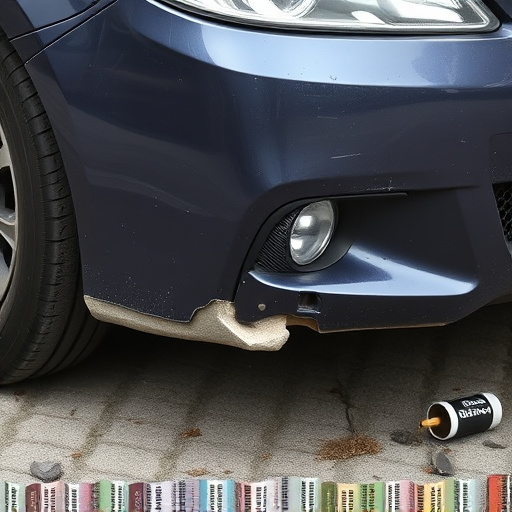

Mercedes corrosion protection is an essential step in ensuring the longevity and aesthetic appeal of a vehicle, especially after repairs. It’s more than just preventing rust; it’s a comprehensive approach to safeguarding the car’s structural integrity and its glossy finish. When a vehicle undergoes panel or weld repairs, whether due to a fender bender or a severe collision, as in auto glass repair or car collision repair scenarios, exposing metal surfaces can make them vulnerable to corrosion over time.

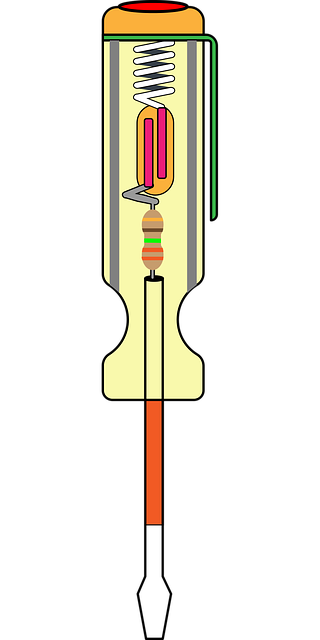

This protective measure involves specialized treatments and coatings designed to shield the repaired areas from moisture, salt, and other environmental factors that can accelerate rust formation. In a vehicle body shop, professionals apply these treatments, often using innovative technologies and materials to create a barrier that mirrors the car’s original defense mechanisms. The result is not just a visually appealing repair but also a durable one, ensuring the vehicle retains its value and reliability for years to come.

Applying Corrosion Protection After Panel or Weld Repairs: Step-by-Step Guide

After completing panel or weld repairs on a Mercedes vehicle, applying corrosion protection is crucial to ensure long-lasting durability and maintain the car’s pristine finish. This process involves several precise steps that, when followed correctly, can safeguard your auto bodywork from future rust and corrosion.

Begin by thoroughly cleaning the repaired area with a dedicated automotive cleaner, removing any dirt or debris. Next, prepare the surface by applying an undercoat primer designed for Mercedes vehicles, allowing it to dry completely. This step primes the metal, creating a protective barrier. Then, using a high-quality Mercedes corrosion protection coating, apply even coats, ensuring full coverage. Let each coat cure as recommended by the manufacturer before adding the final clear coat, which not only enhances durability but also adds a glossy finish that showcases the car’s beauty. This meticulous process, when carried out in a collision repair shop with expert craftsmanship, is key to preserving your Mercedes’ auto bodywork and its original, stunning look.

Best Practices and Maintenance Tips for Longevity of Mercedes Corrosion Protection

To ensure the longevity of Mercedes corrosion protection, best practices should be followed both during and after repairs. When conducting panel or weld repairs, it’s crucial to thoroughly clean the affected areas to remove any grease, dirt, or old corrosion. This prepares the surface for optimal adhesion of the corrosion protection coating. Using the right tools and techniques for the job guarantees a smooth, even application, minimizing the risk of future rust formation.

Regular maintenance is equally vital. After Mercedes corrosion protection has been applied, it’s recommended to inspect the car periodically for any signs of damage or wear. Promptly addressing issues like dents, scratches, or chips in the paintwork can prevent further corrosion. Keeping the vehicle clean and using high-quality car care products helps maintain the protective coating’s integrity. Additionally, ensuring proper drainage and minimizing exposure to harsh weather conditions, such as prolonged sunlight or extreme temperatures, significantly contributes to preserving the car’s body against corrosion, enhancing its overall lifespan.

Mercedes corrosion protection is an essential step in maintaining the longevity and integrity of your vehicle, especially after panel or weld repairs. By understanding the process and best practices outlined in this guide, you can ensure that your Mercedes remains protected against corrosive elements, preserving its value and aesthetic appeal for years to come. Implement the simple yet effective maintenance tips provided, and you’ll be well on your way to keeping your Benz in top condition.